Table Of Contents

Table Of Contents

Energy Conservation Measure (ECM)

Energy Conservation Measure (ECM) improves the energy efficiency of building infrastructure, including heating/cooling/ventilation systems, utility systems, roofs, and windows by cost-effectively replacing the existing systems. cove.tool automates ECM analysis.This article shows how you can run an ECM analysis for your project now.

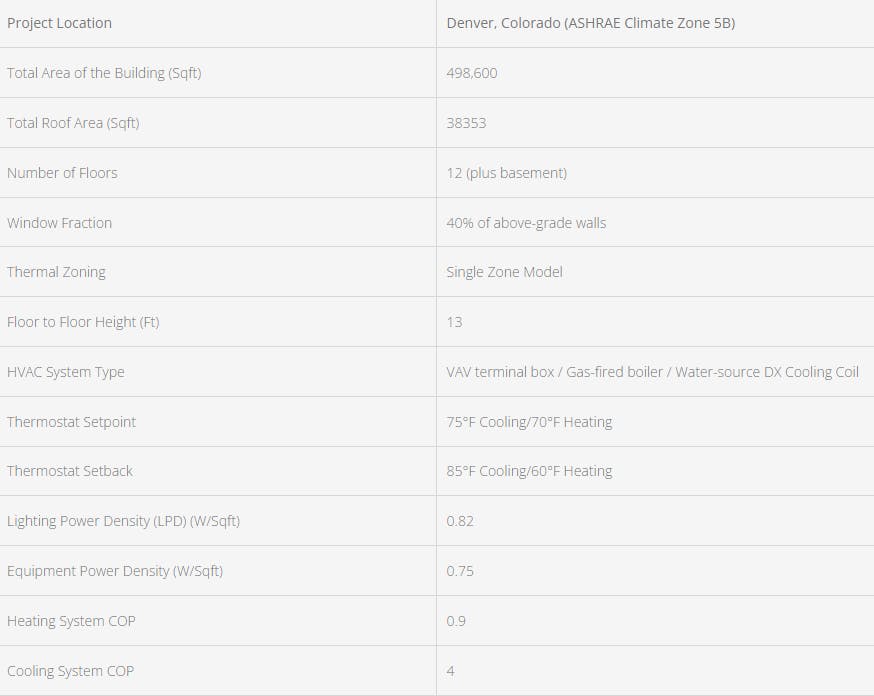

Example Project Description:

The example project is a large office building prototype described by Pacific National Northwest Laboratory (PNNL). Here are some of the building parameters:

Using ECM models, cove.tool can evaluate the impact on the energy performance of the example project described above. These examples represent a small portion of the analysis potential that cove.tool offers to its users.

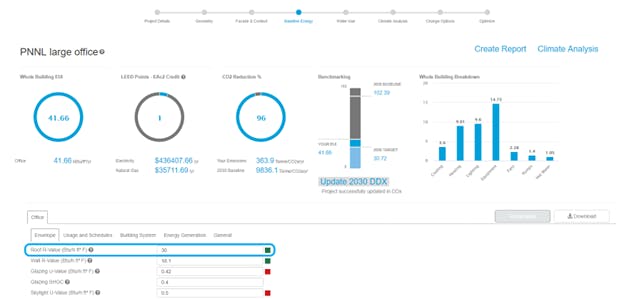

Upgrading Roof Insulation:

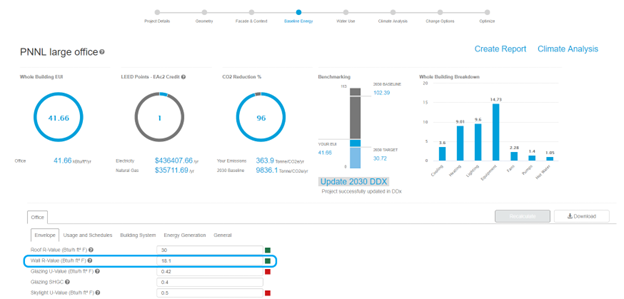

Edit the roof insulation value in cove.tool via ‘Baseline Energy’ << Engineering Inputs (Envelope) >> Roof R-Value.

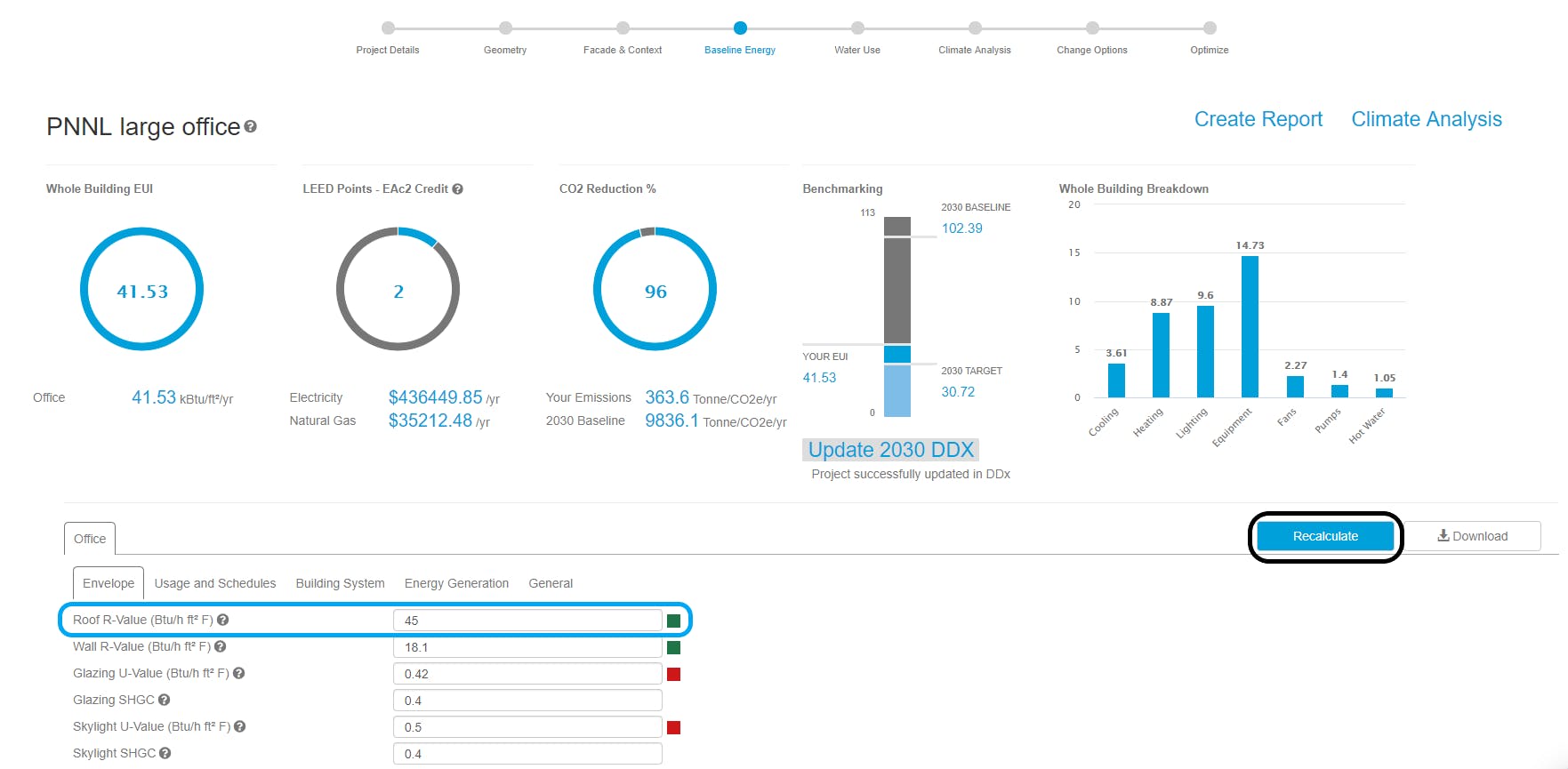

To see the energy impact of an ECM, a user can modify the value in engineering inputs and hit recalculate. The user can record the impact of the EUI difference in real time. The default roof R-value (based on local energy code) is modified from 30 to 45 to record the impact of enhanced roof insulation.

After Recalculating:

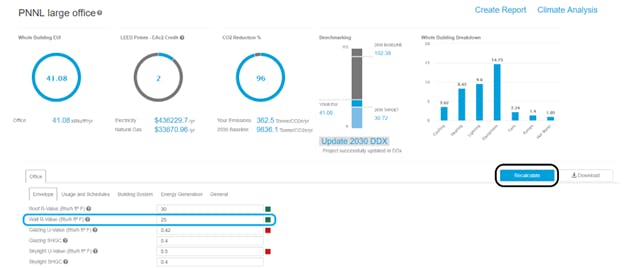

Upgrading the Wall Insulation:

The wall insulation value can be edited in cove.tool via ‘Baseline Energy’ under Engineering Inputs (Envelope) >> Wall R-Value. The default wall R-value is modified from 18.1 to 25 to record the impact of enhanced wall insulation.

After Recalculating:

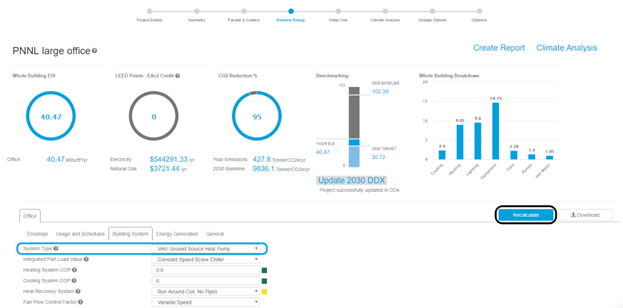

Upgrading the HVAC System:

The HVAC System type can be edited in cove.tool via ‘Baseline Energy’ >> Engineering Inputs (Building

System) >> System Type. cove.tool will automatically adjust the heating and cooling COP values once

the user selects the system type. The COP values can be easily edited. The default HVAC

system of VAV/Water Cooled Chiller/Gas Boiler is changed to VAV/ Ground Source Heat Pump to see

the impact of system type on the EUI.

After Recalculating:

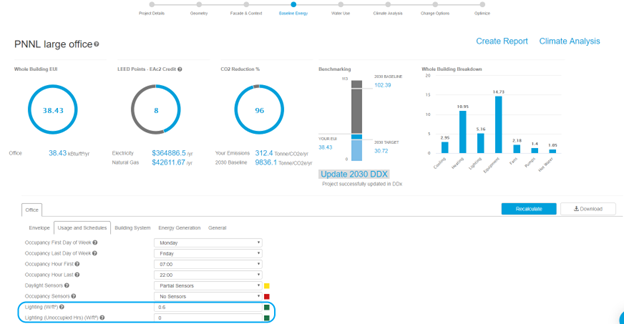

Upgrading the Lighting System:

A) Changing the Lighting Power Density (LPD):

The lighting power density can be edited in cove.tool via ‘Baseline Energy’ >> Engineering Inputs (Usage and Schedules) >> Lighting (W/ft2) and Lighting (Unoccupied Hours) (W/ft2). The default value of 0.82/0.15 for occupied/unoccupied time is changed to 0.6/0.0 to see the impact on overall lighting load.

After recalculating:

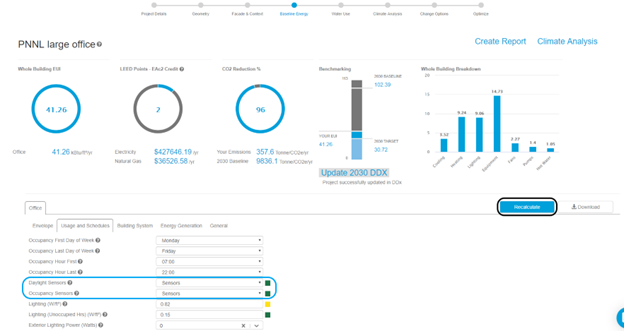

B) Installing the Daylighting and Occupancy Sensors:

The sensors setting can be edited in cove.tool via ‘Baseline Energy’ Engineering Inputs (Usage and Schedules) Daylight Sensors and Occupancy Sensors. The default value of partial sensors/no sensors was changed to sensors/sensors for Daylight and Occupancy Sensors respectively.

After Recalculating:

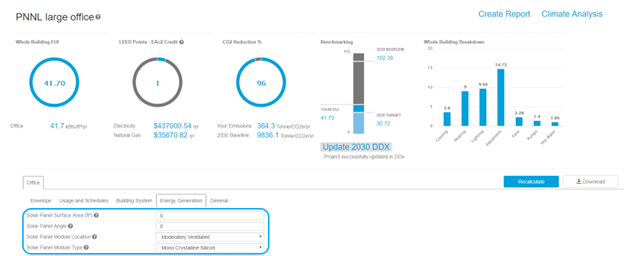

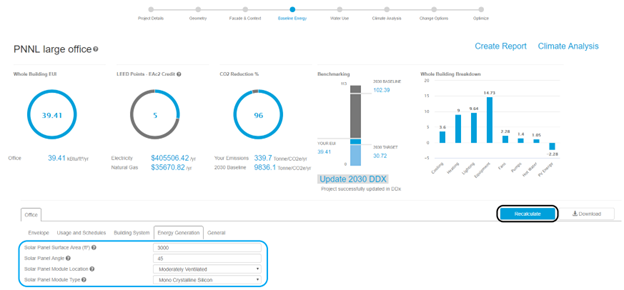

Installing the Solar Panels:

The solar panel installation settings can be edited in cove.tool via ‘Baseline Energy’ Engineering Inputs (Energy Generation) Solar Panel Surface Area, Solar Panel Angle, Solar Panel Module Location and Solar Panel Module Type. The default values of 0/0 for Solar Panel Surface Area and Solar Panel Angle are changed to 3000/45.

After Recalculating:

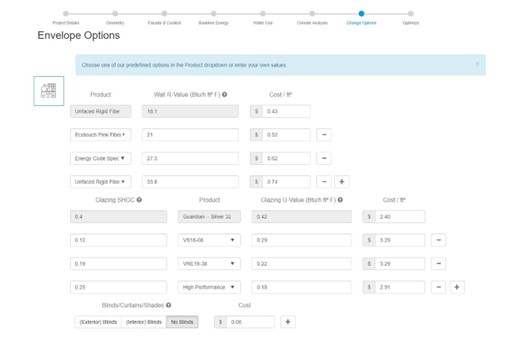

Cost vs. Optimization and ECM Analysis:

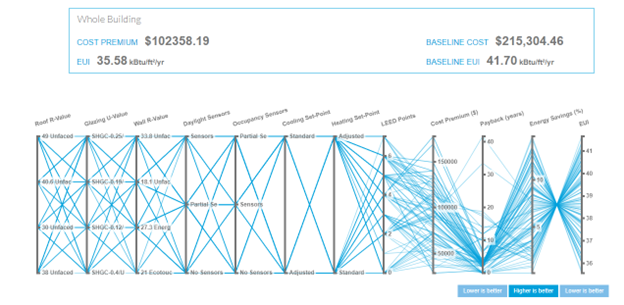

Although energy conservation measures can be implemented one at a time, the true potential of the strategies can be seen as part of the cost vs energy optimization. The feasibility of any ECM implementation is highly dependent on the capital of the ECM and Return on Investment (ROI). With cove.tool, it is easy to calculate the return on investment if the capital cost for the ECMs is known. The main reason is the consideration of the cost as one of the parameters for the analysis.

The user can list the ECMs in the ‘Change Options’ tab provided in cove.tool along with their cost and test them parametrically. With its unique algorithm, cove.tool optimizes the cost-optimal options for the highest energy performance.

After selecting the modification options, the user can keep the default options provided or change them according to the project owner’s requirement to perform the Analysis.

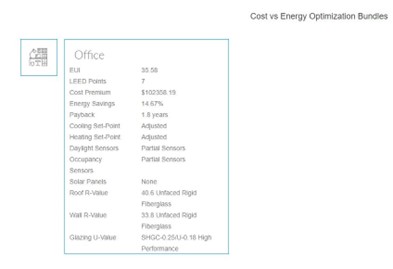

With its unique algorithm, cove.tool arranges the parametric ECM bundle options from low-cost, high-energy performance to high-cost, low-energy performance. The cheapest bundle with the highest performance can be seen in the following figure.

The parallel coordinate graph shows the parametric ECM analysis.