Sport Subaru of Orlando

Project Summary

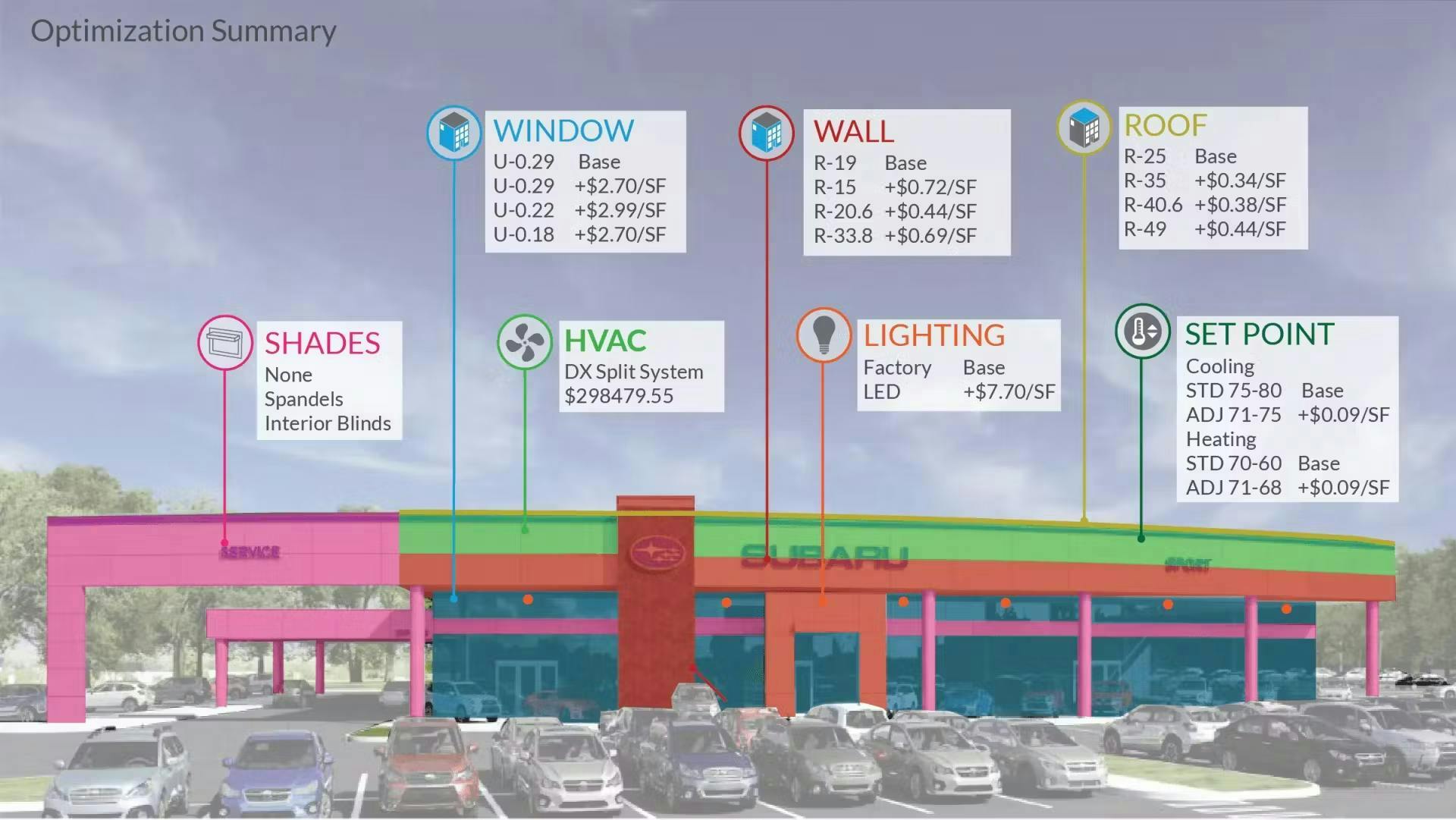

Praxis3 used cove to design the Sport Subaru dealership in Orlando, focusing on energy efficiency and daylight optimization. By utilizing cove’s daylighting and energy analysis, the team reduced lighting power density while ensuring code compliance and cost-efficiency. The platform’s rapid feedback system saved time and costs by reducing the need for design revisions, allowing the team to study multiple alternatives in minutes. This innovative approach helped the project achieve 10% energy savings, optimizing long-term operational efficiency.

⠀

Project Type: Retail⠀

Services Used: Sustainability Analysis

Want to dive deeper?

Explore how cove has helped firms achieve success.