Renovation Project

SUNY Cortland’s largest student residence is starting the new year with a $30 million renovation aimed at making the Casey and Smith Tower complex more modern, comfortable and energy efficient. As with all major construction and renovation on campus, the project will exemplify SUNY Cortland’s commitment to sustainability. The buildings will be upgraded to the Leadership in Energy and Environmental Design (LEED) Silver standard. Renovation projects present a unique opportunity to find the design strategy with the highest impact while balancing the cost. Should the project upgrade lights, or should the team change the HVAC? Should they increase the wall insulation or does the glazing need to be upgraded. Every one of these questions has a 20-30 possible product choices from various vendors, each at a different price point and performance value. The design team must balance all these alternatives while keeping the aesthetic targets on track.

Key to solving this challenge while keeping costs down is to run more design cycles. The project designers at EYP along with Justin Shultz (Senior Building Performance Analyst) understood this and used data driven decision making to find the lowest cost, highest performing option for this project. The team tested a total of 729 possible combinations using the automated cost vs energy optimization. This allowed them to rapidly converge on the best design.

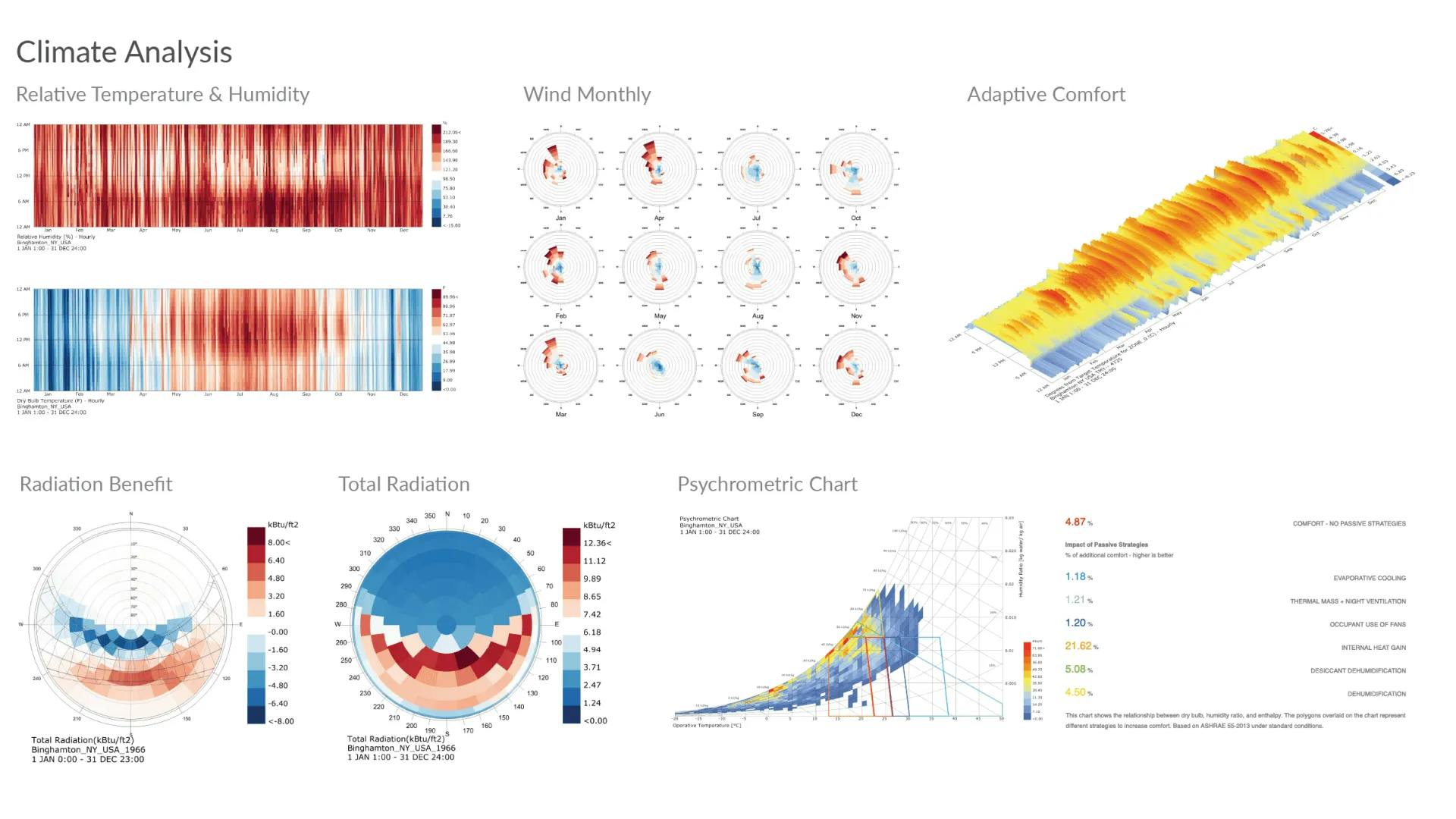

01 Site and Climate Study

The Cortland, New York climate has high relative humidity throughout the year along with mild temperature during mornings and evening. The psychometric chart showcases that de-humidification would allow the building to achieve 5% more comfort without heating and cooling and internal heat gain would allow 21% additional passive comfort. A basic understanding of the existing climate conditions is a vital jumping off point for exploring performance driven design concepts.

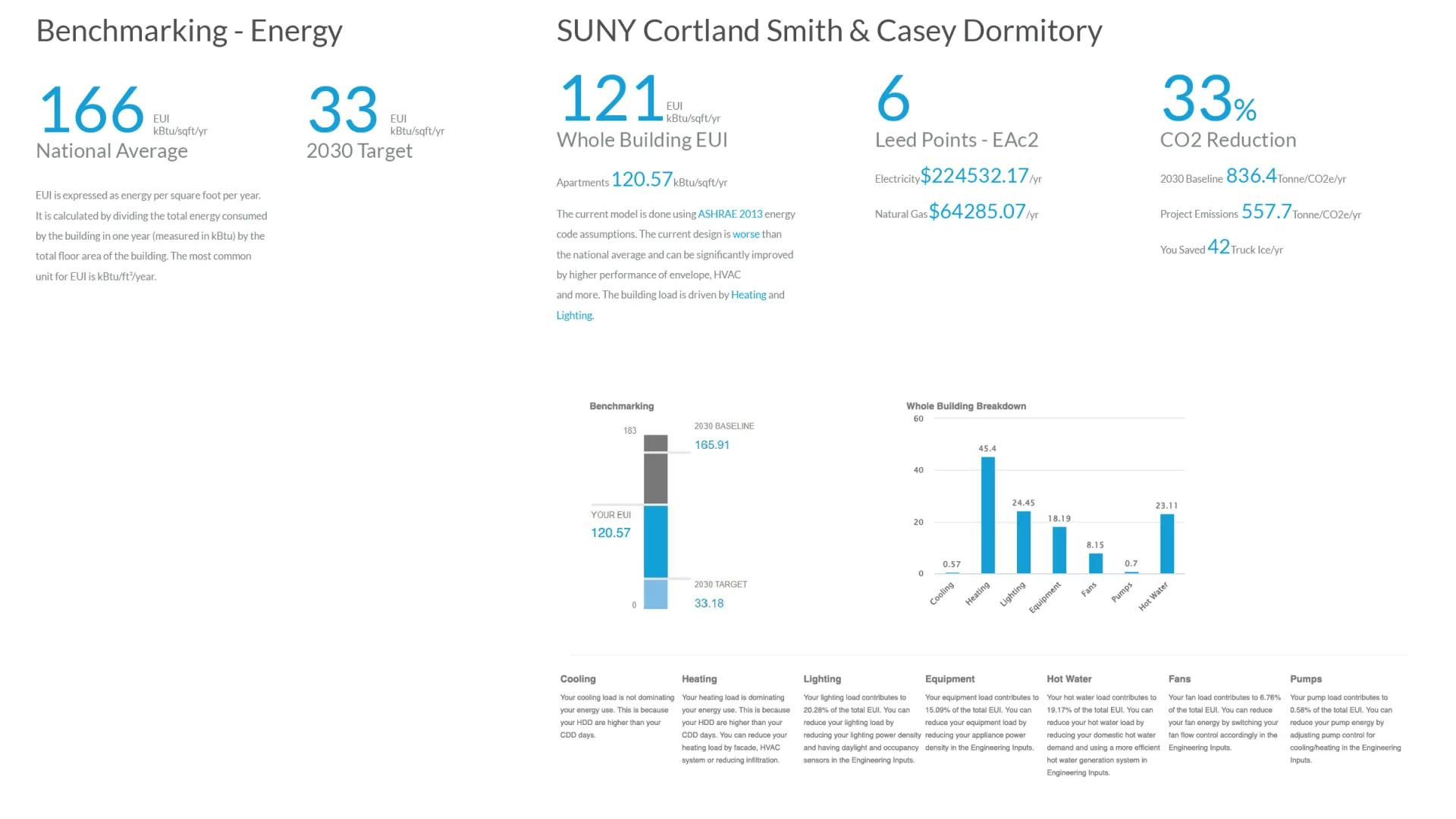

02 Energy, Carbon, and Water Analysis

Starting out with a baseline benchmark average of 166, the design team targeted an EUI reduction of 25% for 110-115 kBTU/sf/yr. Starting with the base minimum requirements to meet the local regulations, the team got to an EUI of 140 kBTU/sf/yr. Setting clear targets is vital when using data driven design. The integrated effort of architecture and engineering with facade optimization along with a high performance radiant system on the "baseline" option allowed the team to achieve a 33% reduction on the operational carbon and get to an EUI of 121 kBTU/sf/yr.

To take the building performance a step further, the team utilized the cost vs energy optimization and achieve the energy targets set out by the integrated team at the beginning of the project. The graphic below showcases the results with 6 potential LEED v4 points for EAc2, 380 Tonnes of Operational Carbon (CO2e) reduction per year, which is equivalent to avoiding 42 truck loads of ice melted every year in the Arctic.

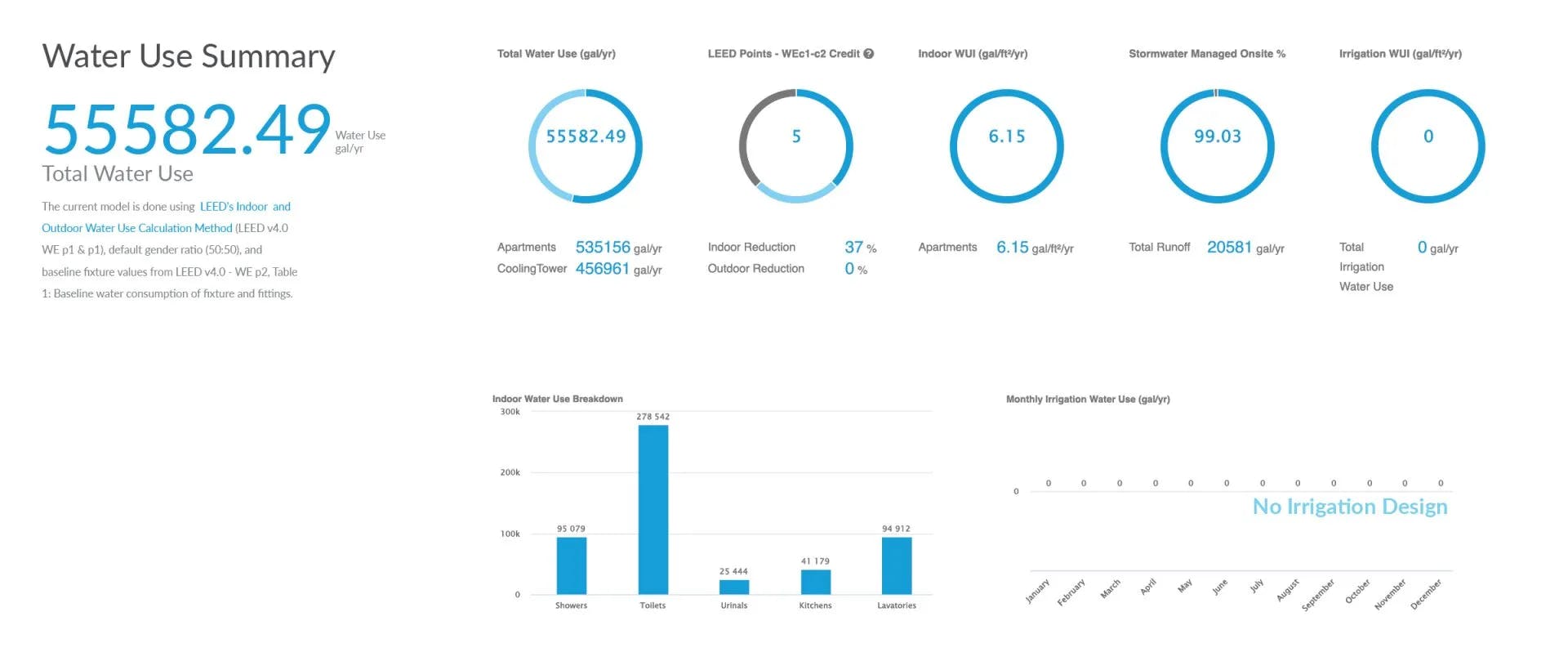

While domestic hot water is not the most dominant load in the new classroom building, the automated platform showcased the water use analysis for indoor and outdoor water usage, along with storm water management. The model showcased opportunities to reduce the indoor water use intensity by using low flow fixtures throughout the project and a potential for grey water use. The diagram below highlights the ability of the design to meet up to 5 LEED points for the water category when using low flow fixtures with toilets being the dominant water use load.

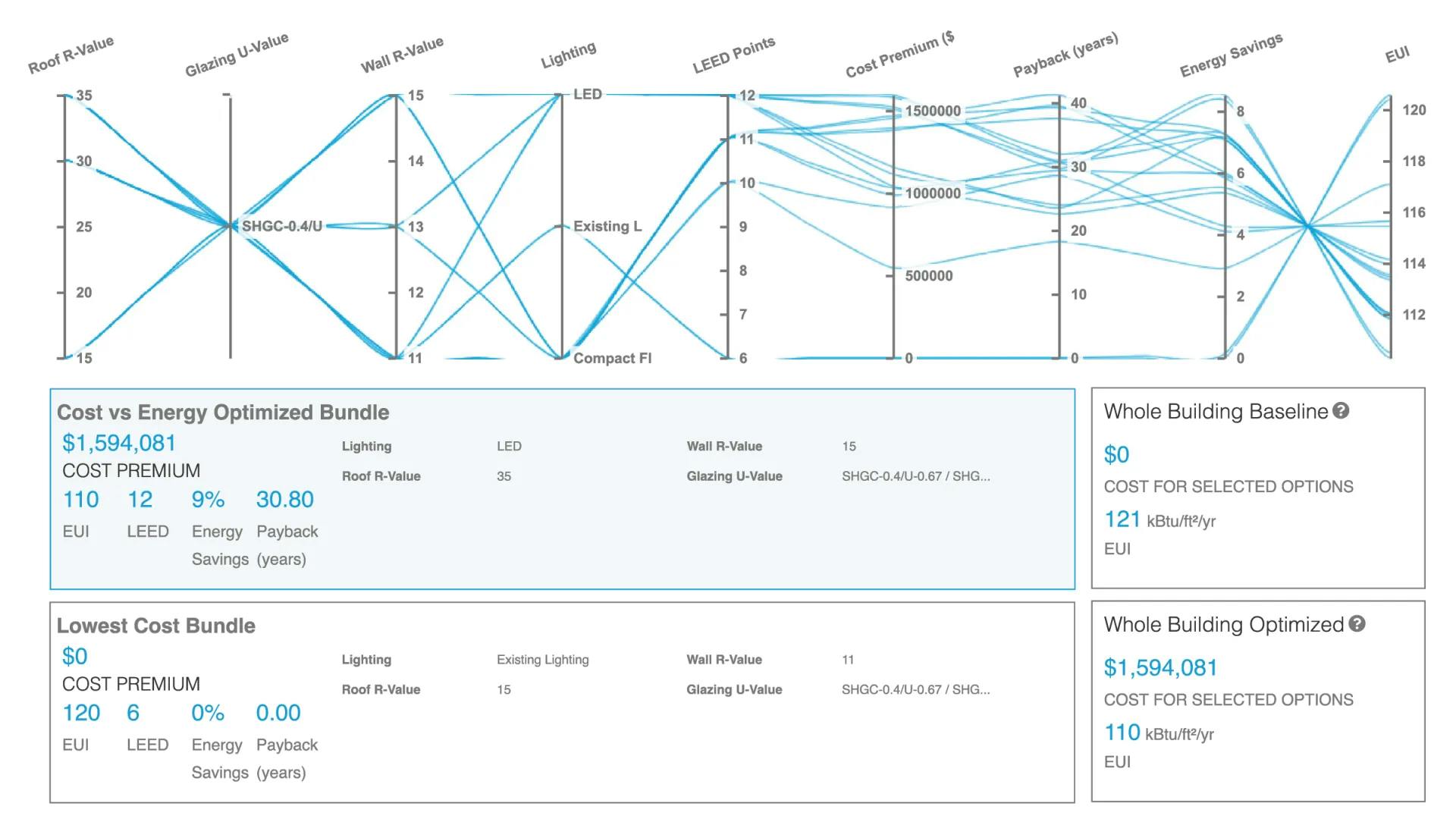

04 Parametric Optimization: Meeting Energy Targets within Budget Constraints

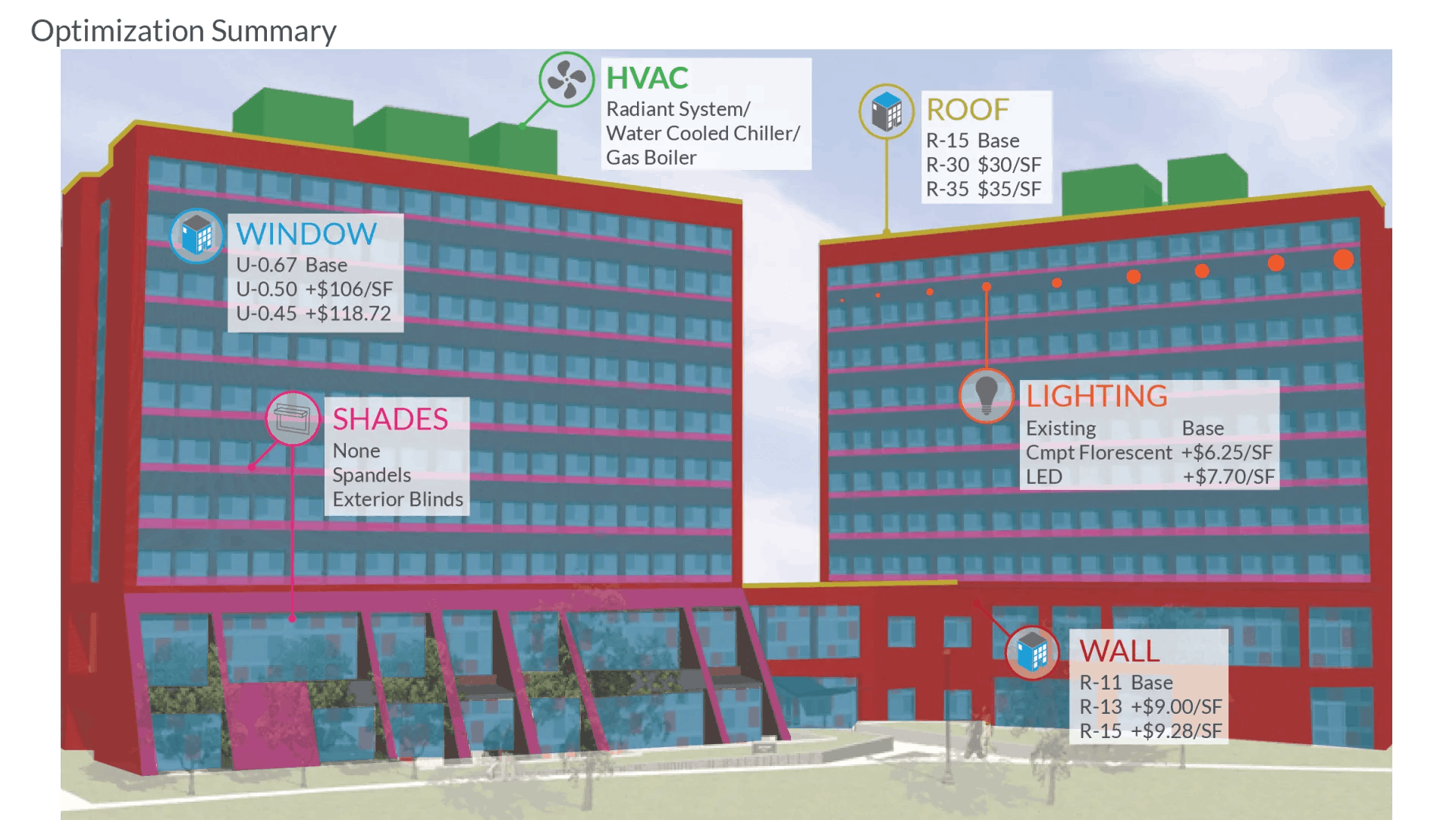

The EYP team collaborated with the architects to further the building's energy performance goals meeting the incredible EUI target of 110-115 kBTU/sf/yr by exploring a range of variables. This is an excellent example of parametric design. In other words, they made a list of all the characteristics of the project they were open to being modified. For example, the HVAC type, the wall R-value, glazing type, and more. The purpose of optimization modeling is to develop bundle recommendations of energy conservation measures (ECM’s) to show various ways of achieving the project’s energy efficiency goals in the most cost-effective manner. These variables utilized for a parametric analysis and an ECM bundling exercise to develop the ‘Optimized Design’ recommendations. In addition to the impact on performance, each variable also had an impact on the project's budget. The holistic cost vs energy optimization allowed the team to study all 729 combination and pick the lowest cost option that allowed them to meet the performance targets. Below are all the options that were studied, along with their impact on the project's budget.

Of all 729 options, the team utilized the dynamic slider to eliminate bundles that did not meet the project’s EUI target. As can be seen from the figure below, any of the three HVAC system options could meet the Target EUI. Using the sliders to parse through the data further, eliminating cost premiums that did not pay back in the lifetime of the building got the team the best upgrade recommendations. As seen the the "Cost Vs Energy Optimized Bundle", upgrades includes: LED Lights, Roof Insulation to R-35, wall insulation to R-15 along with an efficient system type.