Efficient, precise, and cost-efffective sustainability consulting tailored for engineering needs. Utilize advanced resources for early-stage energy analysis, enabling proactive insights that enhance later stages of project development and contribute significantly to sustainability objectives.

role // engineers

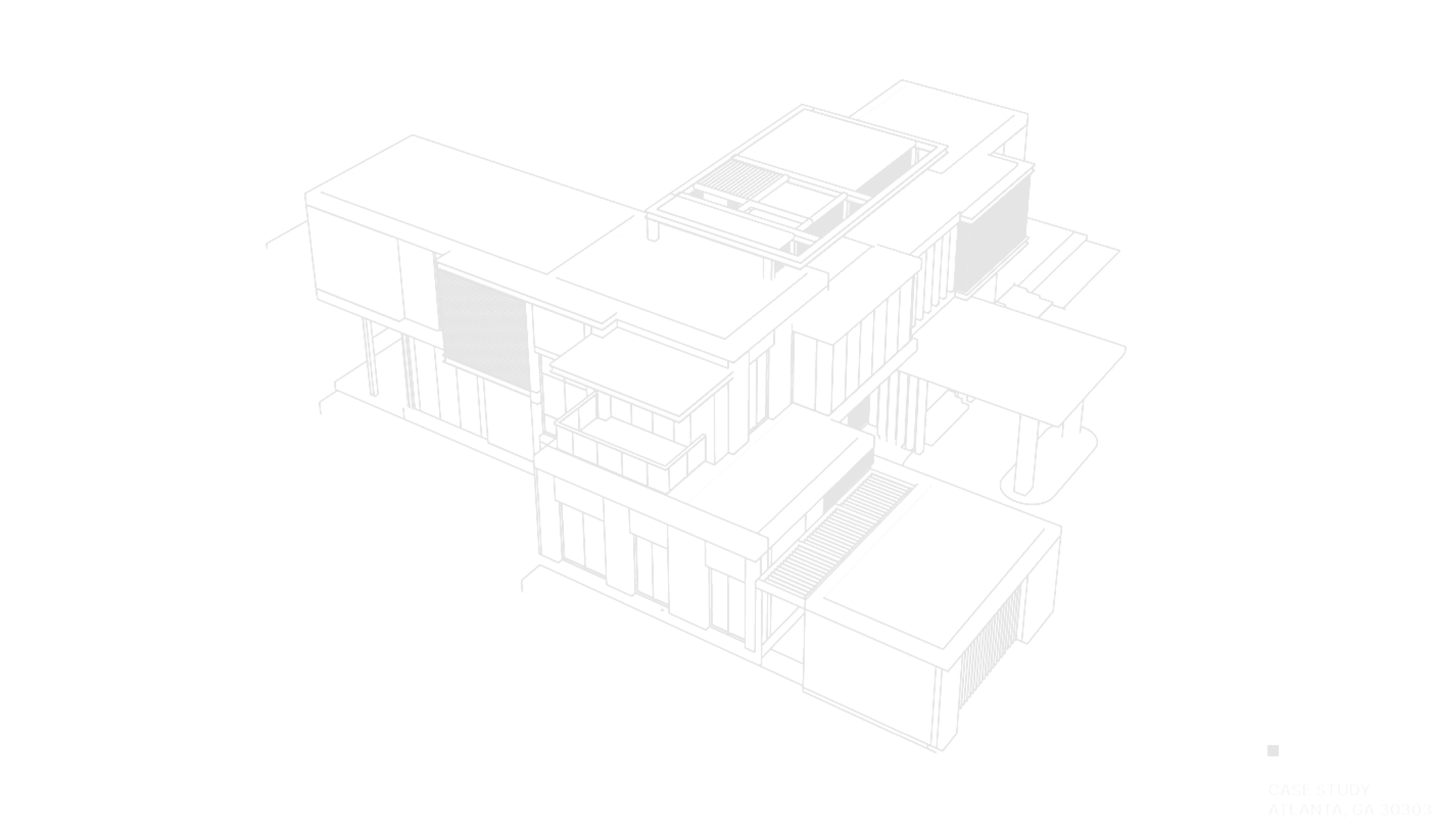

Intelligent early-stage energy insights for Engineers

Engineers using cove.tool

our products

Explore our solution for engineers

We have the services you need for project success.

Efficient, innovative, and comprehensive.

Setting the new standard in sustainability consulting, merging building science expertise with advanced analytics and AI innovations.

Win More Work

With greater design transparency, better communication and beautiful graphics, cove.tool helps win new work and retain existing clients.

Reduce Project Costs

Our AI-powered consulting services, validated by experts, offer a 75% cost reduction per project engagement compared to traditional consultants.

Increase Collaboration

Opportunities for improvement in communication between architects and engineers often arise when quicker answers to questions are needed. By improving speed, smooth out this process and improve collaboration between teams.

Meet Sustainability Goals

We've got you covered from COMCheck to LEED, our full-service sustainability consulting services ensure your goals are met.

Hear from our clients

The facts

cove.tool's sustainability consulting is changing the AEC industry

templated inputs

automated energy codes