Table Of Contents

Table Of Contents

01 Introduction

Looking beyond conventional wisdom requires using data to prove innovative ideas can work especially in the concept stage. With a building performance strategy led by Paul McKeever AIA, the confidential multi-story commercial tower sits in a dense urban neighborhood. Passively cooled with a unique central atrium, the common areas harness the climate avoiding energy use for ventilation, heating, and cooling. The design team used cove.tool to quantify the energy and cost savings. Armed with this data, the team successfully pitched concept to the owner by justifying the return on investment in an unconventional design.

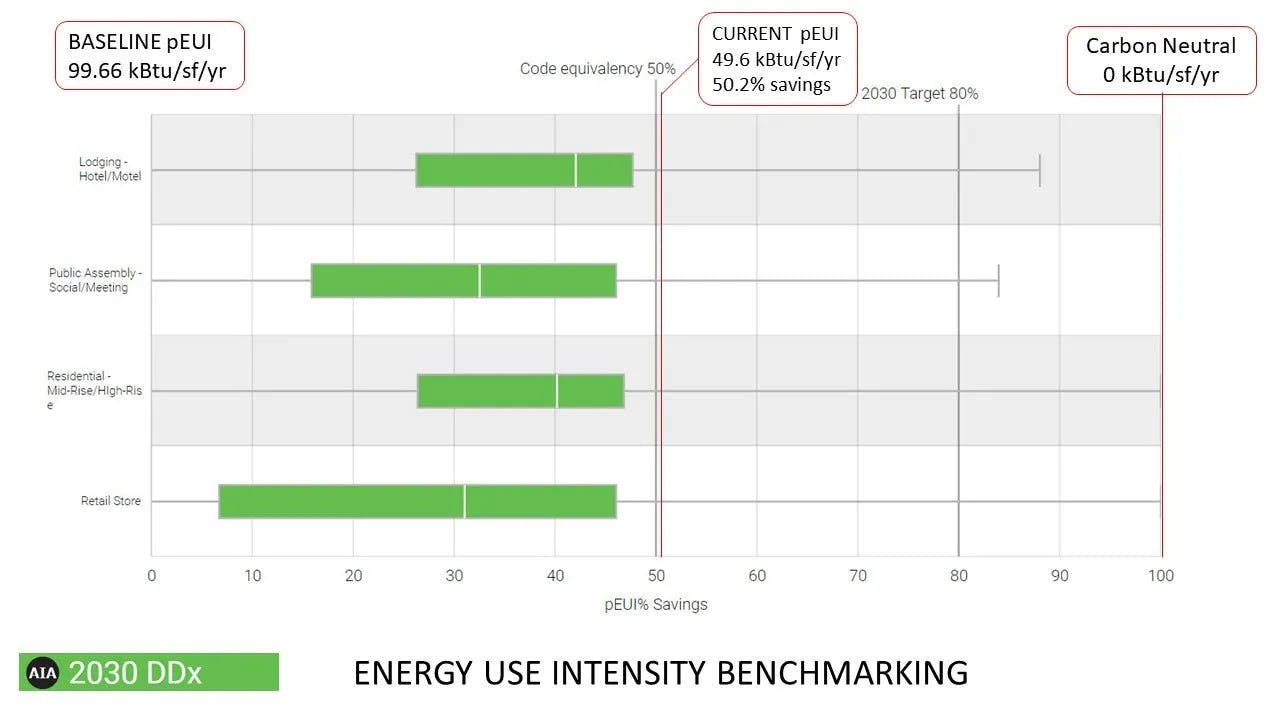

The first step to justifying the concept was identifying the baseline energy consumption for a comparable building and then setting goals for this project. cove.tool played a decisive role by making that analysis iterative and simple. This enabled the team to quickly test out ideas and fine tune them, reaching a cumulative savings of 50.2%.

02 Process

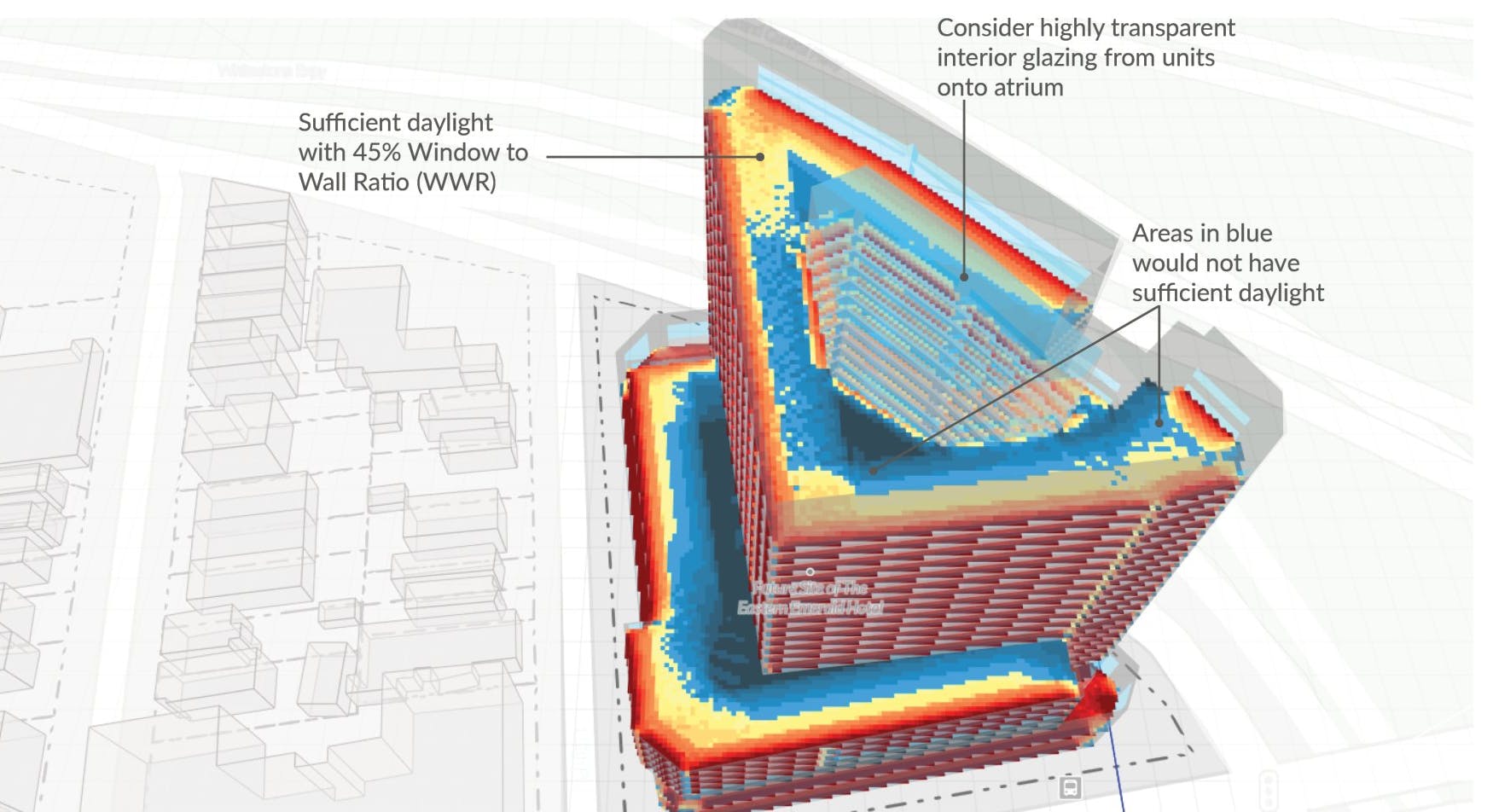

tvsdesign approached the project from multiple angles to get wholistic benefits from an optimized design solution. They analyzed the key aspects of space conditioning, daylight, window to wall ratio (WWR) and use of renewable energy all in-house giving the team a better understanding of the constraints and opportunities.

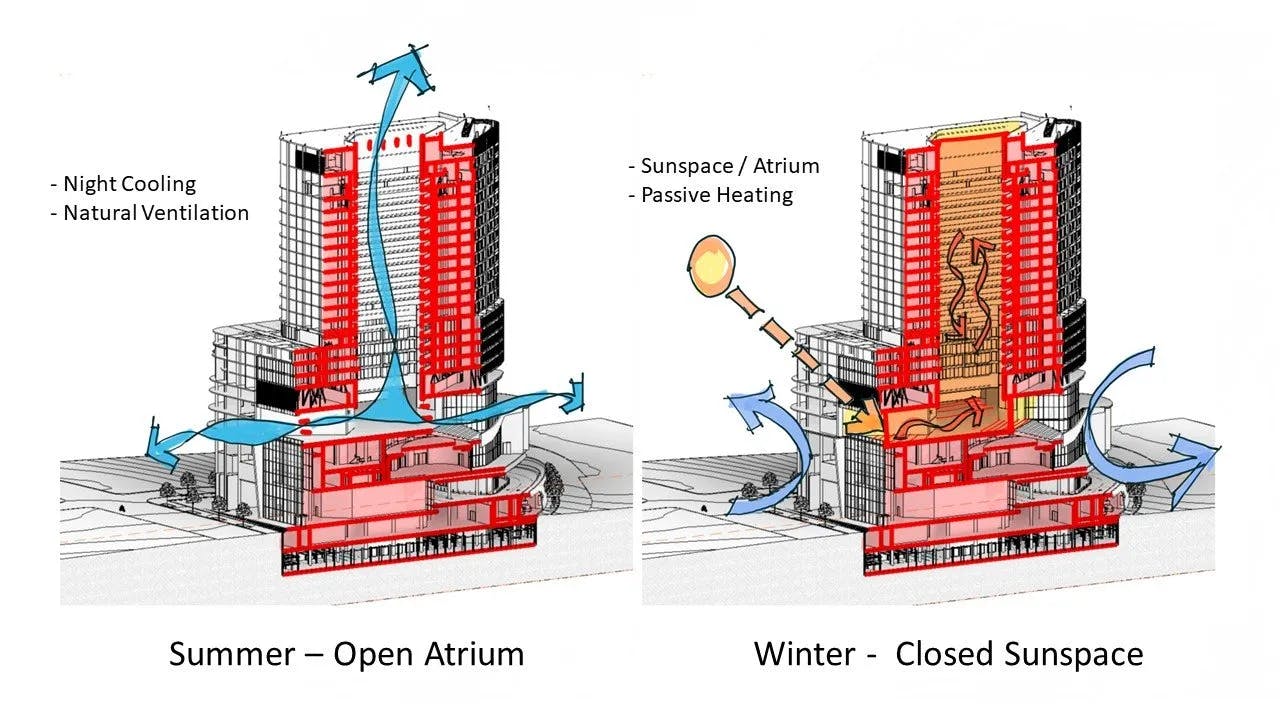

Passive cooling and heating:

The focal point of the design was a central atrium with a seasonal strategy for heating/cooling and natural ventilation. Using cove.tool the design team assessed how much energy could be saved by enhancing the stack effect and allowing for passive strategies like night cooling. Not only did the space serve well during the cooling season (warm weather), but also in the heating season (cool weather) when it can be used as a closed sunspace to trap the heat indoors. All these intuitive design strategies were quantified and assessed for cost versus energy consumption, making a good business case for the client.

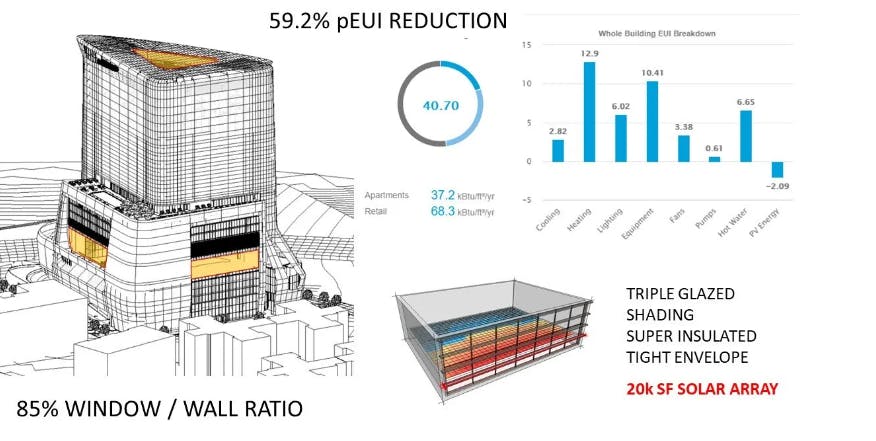

Window to Wall Ratio (WWR) and photovoltaic panels (PV):

The benefit of an integrative tool is that the team could do rapid prototyping, saving them many hours in modeling different iterations. As recommended best practice by the AIA Architect’s Guide to Building Performance, a parametric study was done for different values of the window-to-wall ratio (WWR), along with the use of photovoltaic panels (PV), to compare their combined impact on the project’s energy use intensity (EUI). Using cove.tool’s façade guidance tool, the team swiftly modeled variations of a typical bay with different glass types, shading strategies, and infiltration rates.

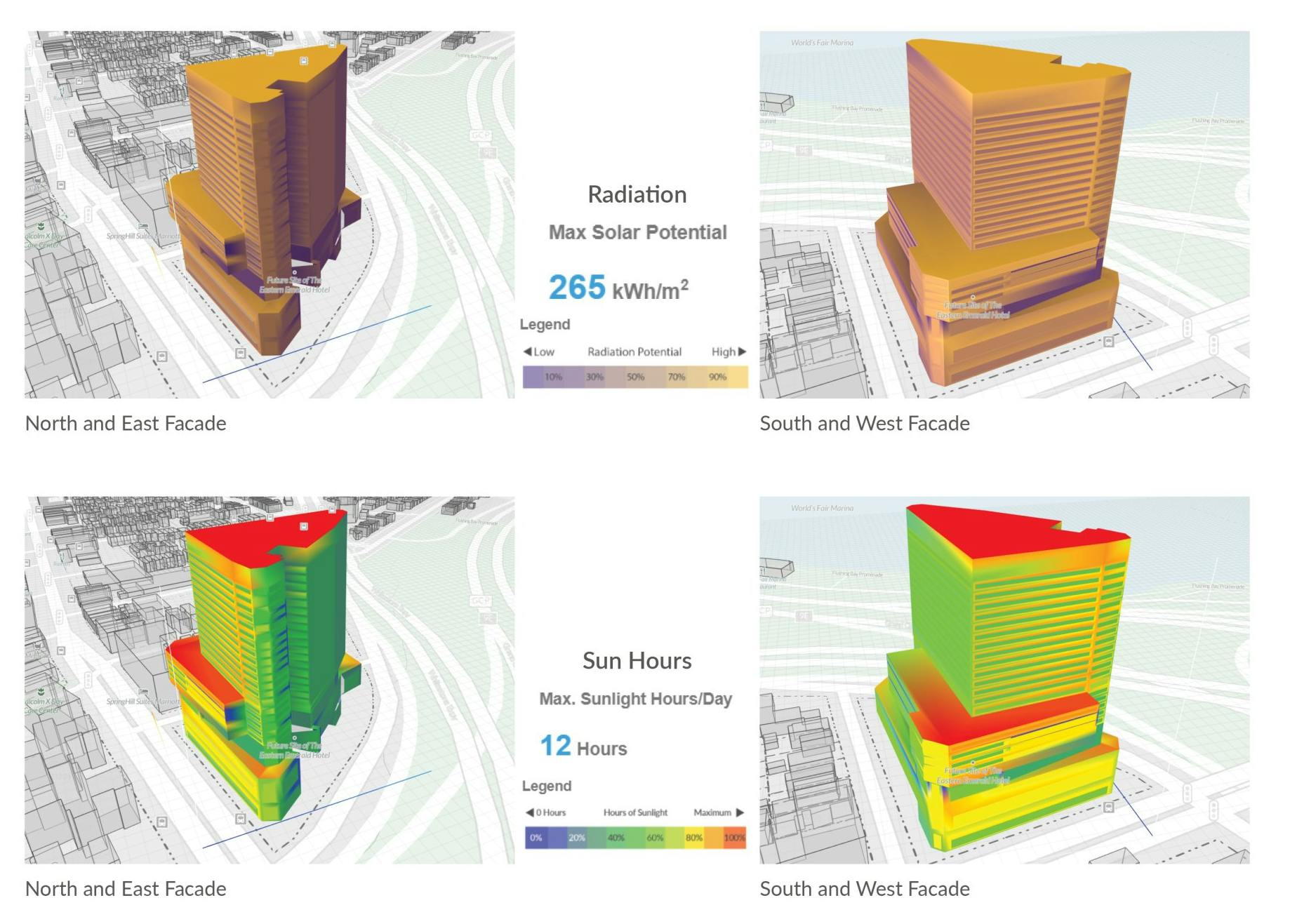

Sun Hours and Radiation Studies:

The project benefited from the Sun Hours and Solar Radiation studies, to optimize the façade details and location of photovoltaic panels. When combined with the iterative WWR studies, the design team was able to customize the fenestration and glass type.

Using these analyses, the design team enhanced façade details for each orientation - selectively adding details like fritted glass and recesses for openings. The full floor plate daylight analysis was very useful to identify the interior spaces that needed transparent glazing to allow more daylight penetration, while limiting the glare (ASE analysis).

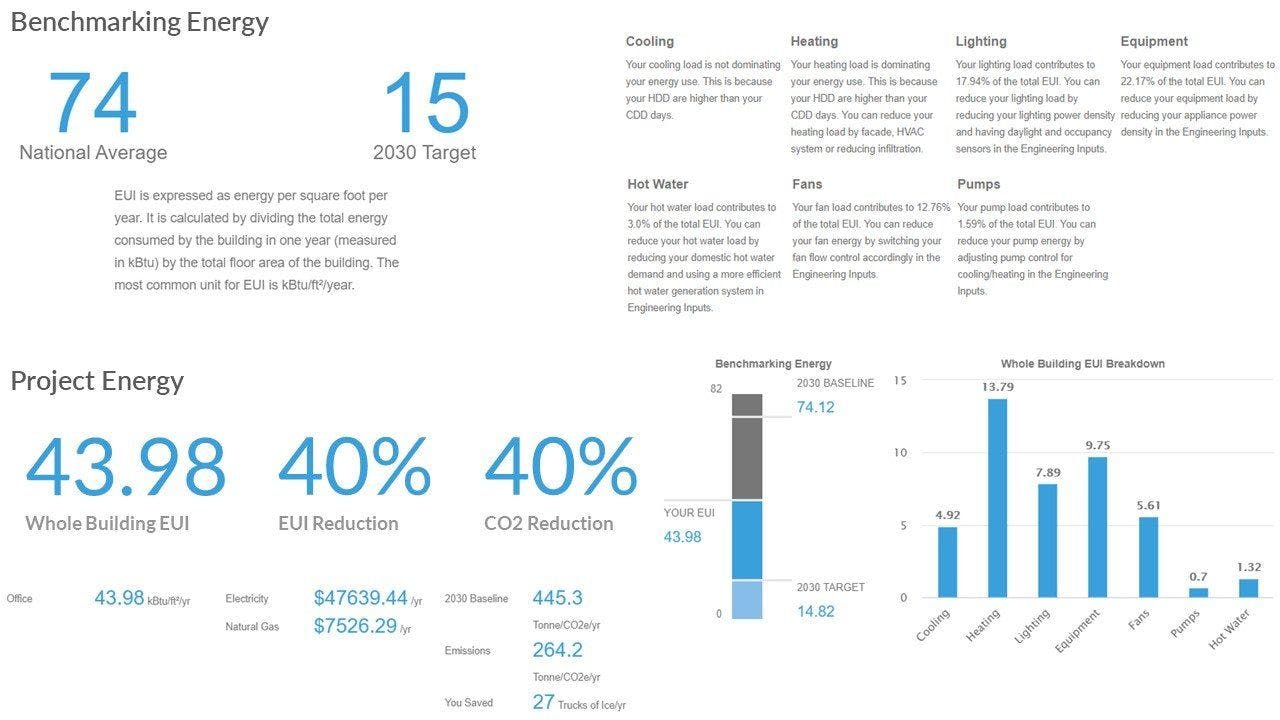

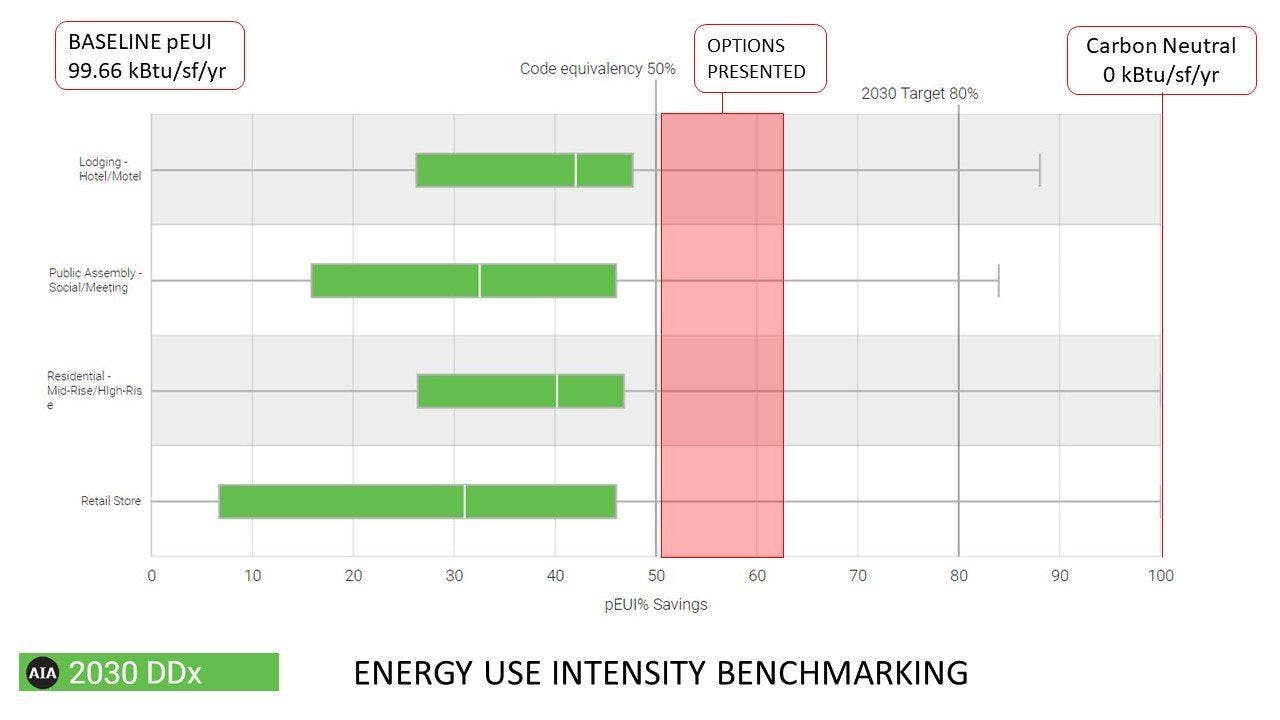

The design team advanced from a baseline Energy Use Intensity (EUI) of 74 kBTU/sf/yr, to a 40% EUI reduction of 43.98 kBTU/sf/yr, making significant progress towards the 2030 goal of being carbon neutral. The team presented options to the client that ranged from 50 to 60% effective energy savings. By optimizing the facades and using photovoltaic panels, among other strategies, the team was able to achieve a 40% carbon reduction as compared to other buildings of this size and type. Hitting the carbon efficiency target was equivalent to avoiding 27 truckloads of ice melted per year.

Even better for the firm, the design team was able to save time and cost typically associated with design revisions after getting the detailed energy model. By understanding and refining the energy strategy as part of the design process, the team stayed closely aligned with the energy model. All of this was achieved as part of an integrated design process where the design concept was validated and refined by data generated by the design team themselves.